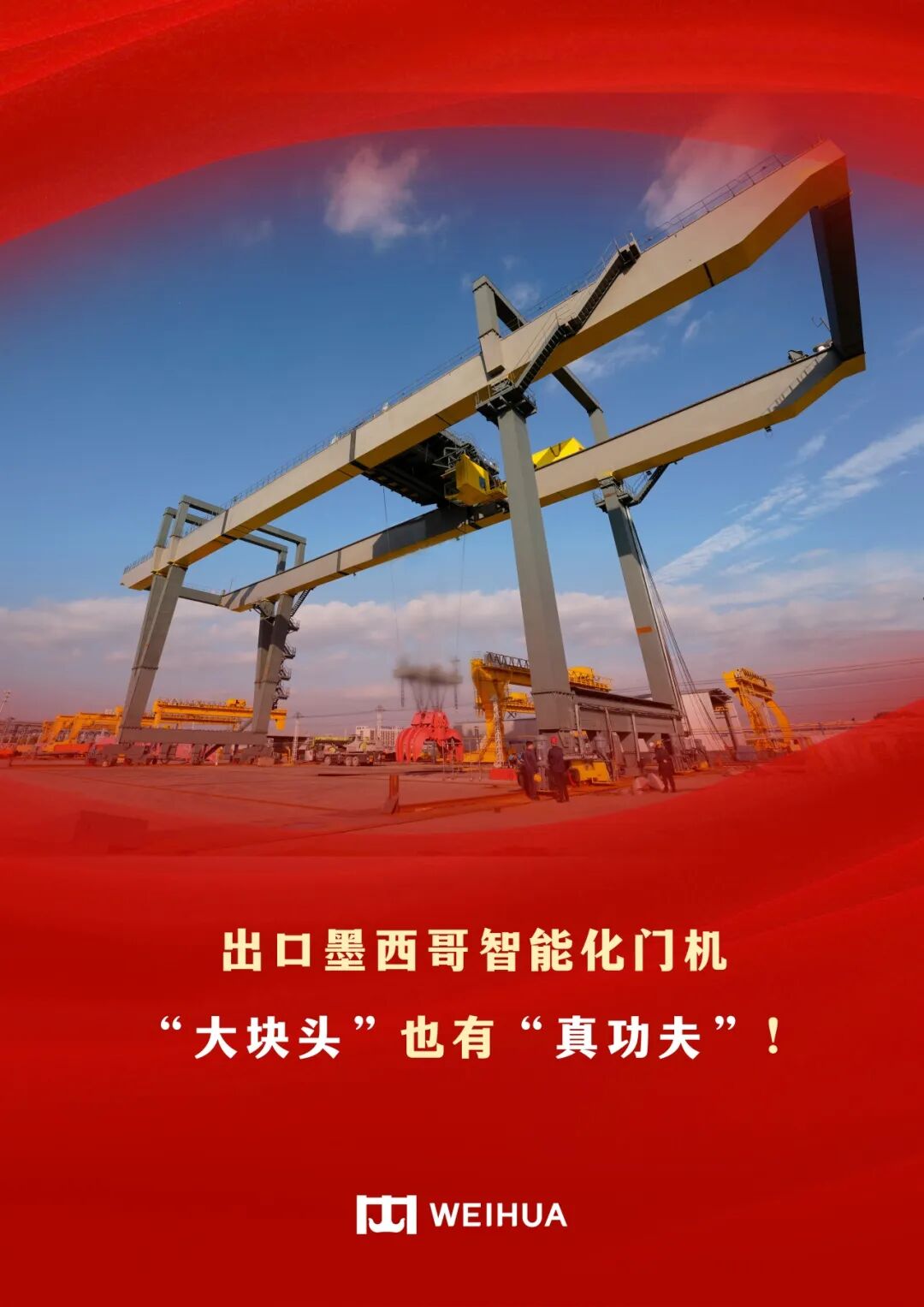

Recently, a loading and unloading gantry crane with a height of 30 meters and a main beam arm span of 85 meters successfully completed its operational acceptance in the Weihua factory area. It is about to cross the ocean and head to a top steel plant in Mexico to engage in busy scrap steel loading and unloading operations.

This product strictly follows the design standards of European and American lifting machinery, and meets customer customization requirements in terms of structural grade, lifting mechanism, and material selection. As an intelligent gantry crane with the highest level of crane operation, it is designed for high-intensity work.

The physique of a 'giant' ensures that there are no blind spots in homework: with a height of 30 meters, a main beam arm span of 85 meters, and a span of 50 meters - this' giant 'physique makes it easy to cover a vast work area.

Agile skills and non-stop efficiency: equipped with efficient and highly reliable loading and unloading bridge trolleys, with a lifting speed of 50m/min and a running speed of over 150m/min, it can shuttle freely in the huge waste yard and is truly a "high-efficiency giant".

Flexible arm, versatile: With intelligent lifting equipment, it can quickly switch between electromagnetic suction cups and hydraulic grab buckets. Both waste disposal sites and grab bucket operations can be easily grasped and absorbed, achieving full coverage of application scenarios.

And these are just its' basic skills'.

The true wisdom of this' steel giant ',

Hidden in its' true kung fu ':

Anti sway "as stable as Mount Tai"

It is equipped with dual skills of mechanical anti sway and electrical closed-loop anti sway, which can make the suspended scrap steel stop swaying in a very short time even during high-speed operation, achieving precise positioning and efficient handling of "fast, accurate, and stable".

Security is as solid as gold soup

The overall design incorporates safety concepts into every detail and builds a comprehensive protection system. The lifting mechanism is equipped with a "sensing" system to monitor the height in real time, and the safety margin of key mechanisms such as the lifting motor, brake, and wire rope is sufficient; The axle pin overload sensor has a 5-fold overload capacity and can sensitively sense off load situations to ensure safe operation.

Reliable 'striving for excellence'

To cope with the extreme working conditions of steel mills 24 hours a day, the equipment strives for excellence in reliability. The core components such as the lifting mechanism and operating mechanism are designed with an ultra long lifespan, significantly improving the overall service life of the machine. Simultaneously adopting advanced international communication systems to ensure stable and uninterrupted power supply and signal transmission.

This loading and unloading door machine, which embodies high-end intelligent technology, is not only a vivid manifestation of Weihua's innovative strength, but also another shining business card for "Made in China" to enter the world's high-end market. Its departure will undoubtedly bring unprecedented efficiency, safety, and intelligent operation experience to a leading steel mill in Mexico.

At present, two intelligent loading and unloading gantry cranes of the same model are being produced at full speed. Soon, the "three brothers" will fight side by side, injecting all-weather intelligent energy into Mexican steel mills!