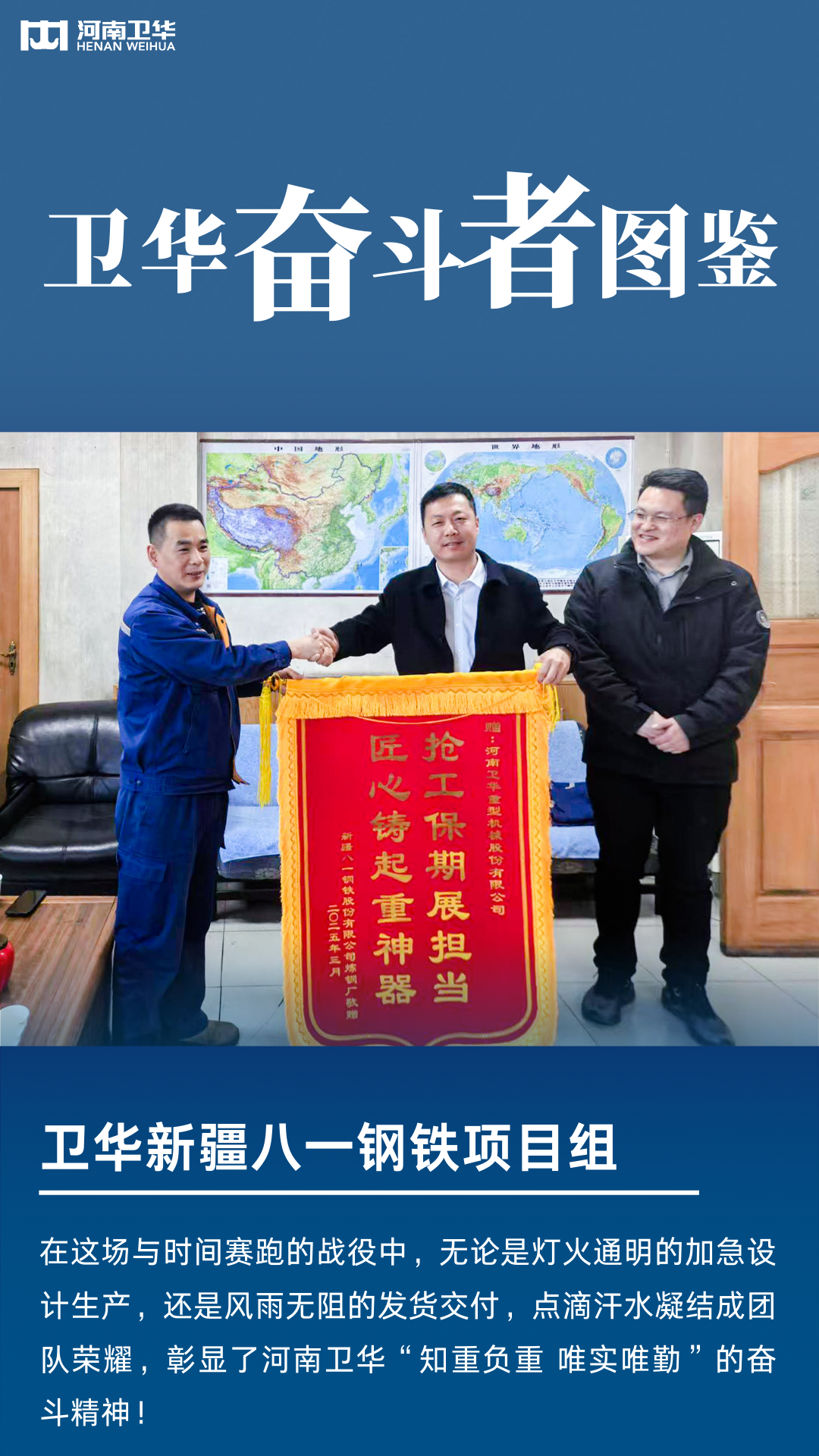

Recently, a heartfelt thank-you letter was sent from Baosteel Group's Xinjiang Bayi Iron and Steel Plant at the foot of the majestic Tianshan Mountains, crossing thousands of miles of rivers and mountains eastward, to the Weihua Intelligent Industrial Park located in the lifting town of the Central Plains, expressing respect and gratitude for Henan Weihua's rigorous, pragmatic, united and enterprising performance in the crane upgrade and replacement project.

In the crane project of Baosteel Group's Xinjiang Bayi Iron and Steel Plant, Henan Weihua, with its excellent matrix project management mode and team collaboration spirit, completed the task that usually takes 120 days in just 47 days.

This feat not only set a new record in the industry, but also won high recognition and praise from customers.

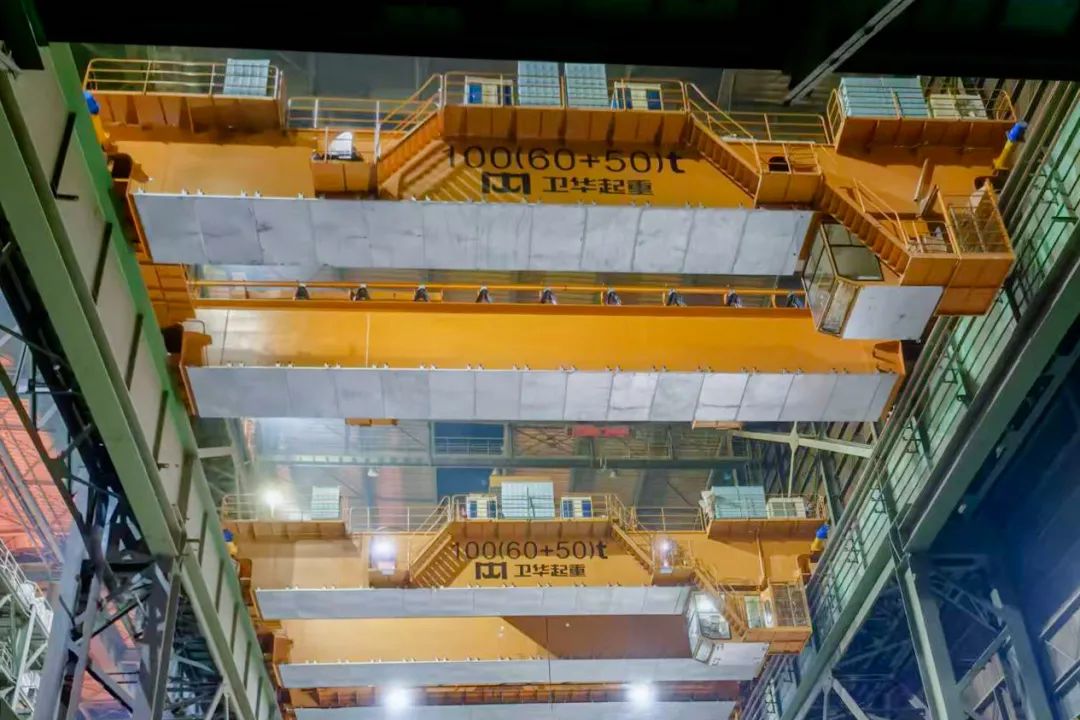

On March 23, 2025, with the successful commissioning of the 120t converter smelting cross crane upgrade and replacement project at Baosteel Group's Xinjiang Bayi Iron and Steel Plant, it marks the unexpected completion and delivery of two new 60t+50t metallurgical cranes.

Behind this is the seamless integration and efficient operation of various links such as design, procurement, production, transportation, installation, and commissioning of Henan Weihua. Faced with the extreme compression of the construction period requirements, Henan Weihua adopts a matrix project management mode to achieve cross departmental collaboration and "all staff charge".

Only by working together can we break through the waves, and only by working together can we overcome difficulties. "This is the common voice of the project team members.

When customers demanded almost stringent project deadlines, the Henan Weihua team did not back down, but instead rose to the challenge. Multiple departments including marketing, technology, procurement, production, and logistics worked together to overcome one challenge after another through efficient communication and teamwork, ensuring that every link was pushed forward according to plan.

At the beginning of the project, the supply cycle of key components such as motors and reducers specified by the customer became a major challenge. Pan Weijie, the sales manager of Henan Weihua, decisively proposed to arrange a dedicated person to stay at the main component suppliers to follow up and urge them, and requested the customer's assistance in coordinating the delivery time of purchased parts. The customer was moved by Weihua's sincerity and professionalism, actively cooperated, and finally successfully solved the supply problem.

The technical team has also demonstrated strong capabilities. Four technical engineers have clear division of labor and quickly overcome multiple technical bottlenecks such as equipment selection and process optimization. They not only translate customer needs into product design language, but also ensure accuracy and safety during the lifting process through repeated simulations and simulations.

The production team works day and night with the spirit of "every second counts" to ensure the smooth progress of every production process. When faced with the problem of vehicle scheduling, project manager Chen Chong made a decisive decision: to send an additional driver to rush to the site without stopping, ultimately ensuring the timely delivery of goods.

Entering the installation phase, the real test has just begun. The single main beam of a 60t+50t crane weighs over 40 tons, and the difficulty of precise lifting in a limited space can be imagined.

In order to save time, multiple tasks were cross operated, with nearly twenty personnel working simultaneously on each crane beam box working surface. The installation supervisor Zhang Yunfei stayed up all night watching the site. The high-intensity work consumed a lot of physical energy from the construction personnel, but everyone still persevered.

Through the joint efforts of all members, on March 23rd, both devices were installed and debugged, and officially put into production.

Weihua 60t+50t train smoothly put into operation

The customer is extremely satisfied with the product quality and service performance of Weihua, and awarded the banner: "Crafted with ingenuity, the crane is a masterpiece, and we are committed to working hard and ensuring timely delivery

The successful delivery of this project not only enhances the equipment level and production efficiency of Baosteel Group's Xinjiang Bayi Iron and Steel Plant, but also establishes a good brand image for Weihua.

The journey is endless, and the struggle has no end. On this path full of challenges and opportunities, Weihua people will continue to uphold the spirit of "knowledge is heavy, burden is heavy, practicality is only diligence", forge ahead, constantly explore and innovate, and create greater value for customers.