In the "China Intelligent Manufacturing 2025 Plan", intelligent manufacturing is the main direction of attack, a major trend and core content of the future development of manufacturing industry, but also the fundamental path of China's manufacturing industry from big to strong. Weihua is based on exploring intelligent production, intelligent products and intelligent services, promoting the upgrading of the lifting logistics industry, achieving win-win cooperation and being the pioneer and explorer of the intelligent industry.

一.Anti-sway function

1.Based on continuous calculation of the angle and height of the rope, the swing of the load can be automatically eliminated during the crane lifting operation, making the operator safer.

2.Devices without anti-shake function need to wait for the load to sway for a long time due to inertia. If you try to prevent and reduce the sway, the working time will be greatly extended.

3.The sway of the load increases the risk of collision of the lifting object and increases the probability of an accident.

4.The intelligent anti-sway system of the crane automatically turns on the anti-shake function after the system is started, and it is automatically put into operation during each lifting process. This function also fine-tunes the operator's speed command to ensure that the load can run smoothly from any position, just like the car we drive in the automatic gear position. When you are familiar with the operating characteristics, you can only be responsible for the "throttle and brake", thus reducing the operation. Difficulty.

Advantages: Increase the safety of operation, reduce the difficulty of operation, reduce the load lifting time, reduce the wear and mechanical impact of crane parts, and extend the service life of equipment.

二. Vertical line function

1.This function is based on the CTS intelligent program design and development, which can eliminate the lateral tension of the wire rope, maintain the vertical state of the wire rope, and can effectively assist the load to reverse.

2.No need for multiple frequency and multi-button operation, single button can be realized after turning on the function, which is simple and convenient.

3.Effectively reduce the impact of load reversal, prolong the service life of equipment, shorten the load cycle, so that the crane can work effectively under the condition of flexible stress curve, also can replace some of the work of reversal tooling, improve efficiency and safety, and reduce the investment of site and equipment.

、

、

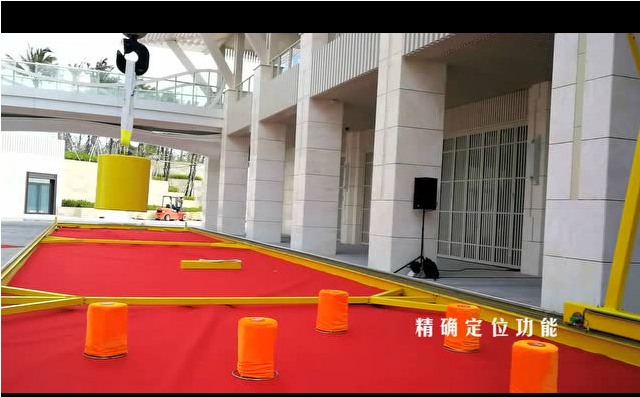

三.Precise positioning function

1. Precise positioning function can be completed by two buttons on the operation interface or remote control handle. When using, just select the target address of the load in the automatic operation interface, click the execute command button, the crane can reach the selected target position accurately.

2.Precise positioning can help the operator save time. When we need to repeatedly execute the same operation process in the same position, in addition to the traditional manual operation mode, we can also start the automatic operation and automatic load lifting of the device by starting only one command information. First set the starting point, path and target position of the equipment operation. Through the deployment of the intelligent program, select the required route and starting point, and the equipment will automatically avoid the obstacle to the specified target position according to the planned path. When the load is removed, it can be returned to the starting point with one button. According to the process requirements, the intelligent program automatically returns to the starting point after receiving the confirmation signal.

3.This function can realize the planning of the target point, saves the operation time, improves the production efficiency, and provides the necessary conditions for realizing the material handling of the intelligent workshop.

四. Pushing catch follow up function

This function is suitable for use on light and small tonnage equipment. It requires simple and precise positioning of the production line, which can make the operation more agile.

The system is controlled by intelligent program. After opening the function, the light load can be sent to the required position by simple push-pull action without any other keys. The method is simple and reliable. It is the best choice for precision assembly and various processing lines.