In the "China Intelligent Manufacturing 2025 Plan", intelligent manufacturing is the main direction of attack, a major trend and core content of the future development of manufacturing industry, but also the fundamental path of China's manufacturing industry from big to strong. Weihua is based on exploring intelligent production, intelligent products and intelligent services, promoting the upgrading of the lifting logistics industry, achieving win-win cooperation and being the pioneer and explorer of the intelligent industry.

Accurate jog function

1. Jog can control the load more accurately. After starting this function, the operator can perform precise operation with the button and the operating lever without frequent jogging, no need to operate the contact time according to experience, thus greatly increasing the operating lever. The switching commands for movement and button are converted to precise displacement commands. This intelligent function helps operators to issue automated commands, precisely control load displacement, improve handling safety and convenience, and provide reliable protection for customer equipment assets.

2. The function can be set at a micro-speed through an intelligent program on the setting interface. It can set the displacement between 2-100mm at will. When the moving object is close to the predetermined target, it can start the point-motion function. After activation, each point-motion or long-distance operation is set to the target, which can help customers solve the problem of running at a fixed speed within a limited distance, accurately controlling the load to reach the designated position, increasing the safety and convenience of operation, while better protecting the safety of surrounding property, reduce the risk of impact and collision.

Intelligent obstacle avoidance function

1. The crane starts running under the condition of automatic path planning. When new obstacles appear in the original open path, the crane intelligent system first detects and judges automatically, stops running, and then chooses the channel which can avoid obstacles after intelligent operation. Under the condition that the channel allows, the crane can automatically avoid running.

2. This function is mainly used in unmanned workshops or places where the operator may be in danger of colliding with objects temporarily appearing on the ground due to fatigue work, which can effectively improve safety and work efficiency.

Preset track run

1. The cycle of operation can be completed by presetting the trajectory through the operation interface or two buttons on the remote control handle. According to the field process requirements, more than 100 target locations and 16 starting locations can be set. When the crane is used, only the target address of the load is selected in the automatic operation interface, and the command button is clicked, the crane can automatically reach the preset target location.

2.Preset trajectory can help operators save time, when we need to repeatedly perform the same operation process in the same location, in addition to the traditional manual mode of operation, we can only start a command information to achieve automatic operation of equipment and load lifting. Firstly, the starting point, path and target position of the equipment are set. Through the deployment of intelligent program, the required route and starting point are selected. The equipment will automatically avoid obstacles and reach the designated target position according to the planned path. When the load is unloaded, the crane can return to the starting point by one key, or according to the process requirements, after the intelligent program gets the confirmation signal, the crane automatically executes the return to the starting point.

3.This function can realize the planning of the target point, save the operation time, improve the production efficiency, and provide the necessary conditions for the material handling of the intelligent workshop.

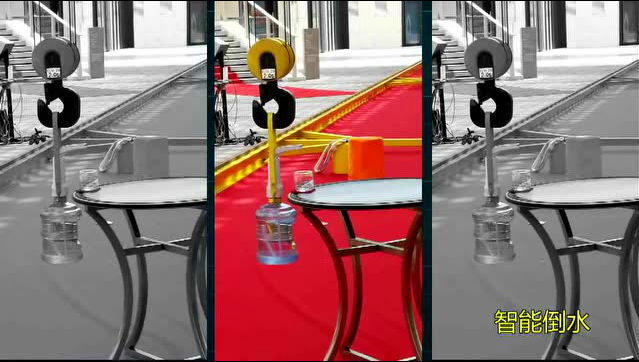

Smart pouring demonstration

The intelligent watering device is fixed on the hook, and after the crane reaches the designated position, the water injection operation is implemented. This function mainly demonstrates the continuous movement of a series of intelligent functions such as automatic planning path, precise positioning, micro speed operation, anti-collision, micro speed lifting and automatic obstacle avoidance when the intelligent crane is unmanned, showing the crane carrying material handling and flexibility in the air. The technical ability of control can be more applied and promoted in innovative material handling!